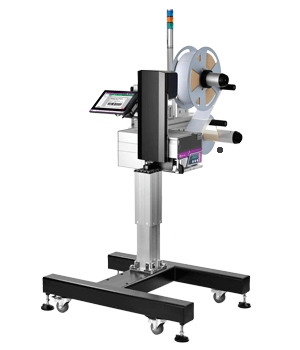

2200 Pallet Markem-Imaje 2200 Pallet provides a flexible range of pallet labeling solutions, from simple single face labeling to full GS1 compliant pallet labeling.

Plastic Films

|

Corrugate

Confectionery

|

Personal Care

|

Pet Food

|

Dairy

|

Cosmetics

|

Food

|

Beverage

Print and Apply Labeling

Low | Medium | High

Markem-Imaje 2200 Pallet provides efficient and reliable GS1 compliant pallet labelling solutions.

Your challenges

You are looking for a pallet labeling solution that will provide reliable, consistent label application in order to meet retail and supply chain demands and reduce the risk of costly product recalls. You need a solution that will maximize the availability and efficiency of your production line, with low operational intervention required and no production downtime. You require a labeling system that will facilitate product traceability and inventory control, as well as allow for data control or integration to a local or central ERP solution.

Our solutions

Markem-Imaje 2200 Pallet print and apply systems are used to identify pallets in increasingly automated environments. The 2200 Pallet system can be easily integrated onto any production line, providing outstanding print quality and precise label application to deliver fully compliance pallet labeling across your supply chain. It improves inventory control, logistics flows and secure pallet identification in the unfortunate occurrence of product recall.

Key benefits

The Markem-Imaje 2200 pallet industrial labeling machine series provides faultless traceability with optional inline barcode validation, and high-performance printing of single or dual label application. Designed to maximize your uptime with a simple user-friendly interface and several key features that reduce line stoppages, while guarantying operator safety with an automatic stop function. With Markem-Imaje’s CoLOS software package dedicated to pallet management, each pallet benefits from a unique code that allows it to be traced from the moment it leaves the production line to its arrival at its final destination.